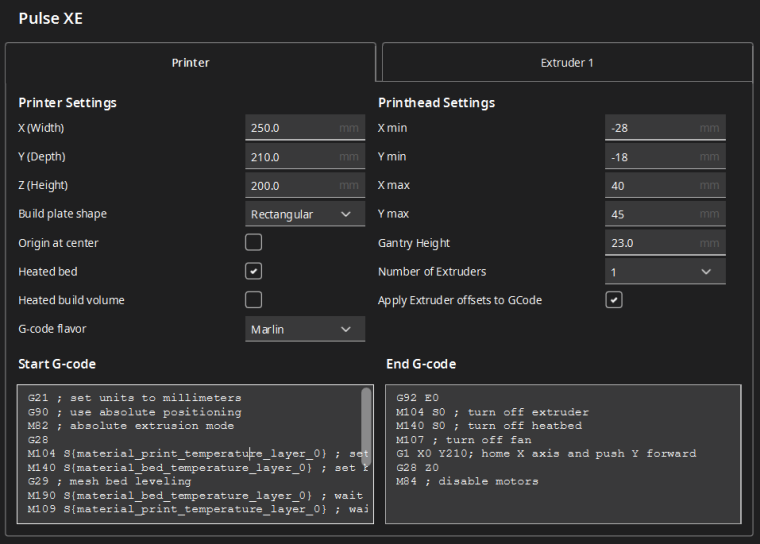

I have a working profile in that Cura, it's based on this profile: https://help.matterhackers.com/article/210-pulse-cura-configuration but I found that importing it as the guide suggests is a bit buggy. I did the following To set it up in cura:

settings>Printer>add printer

Add non-network printer>custom FFF Printer

Copy these settings

Start G-code:

G21 ; set units to millimeters

G90 ; use absolute positioning

M82 ; absolute extrusion mode

G28

M104 S{material_print_temperature_layer_0} ; set extruder temp

M140 S{material_bed_temperature_layer_0} ; set bed temp

G29 ; mesh bed leveling

M190 S{material_bed_temperature_layer_0} ; wait for bed temp

M109 S{material_print_temperature_layer_0} ; wait for extruder temp

G92 E0

G1 X5 Y5 Z10 F1800

G1 E20 F100

G1 X100 Z0.3 E45 F900

G92 E0

G1 E-2 F2400

End G-code

G92 E0

M104 S0 ; turn off extruder

M140 S0 ; turn off heatbed

M107 ; turn off fan

G1 X0 Y210; home X axis and push Y forward

G28 Z0

M84 ; disable motors