Pulse XE Custom Parts

-

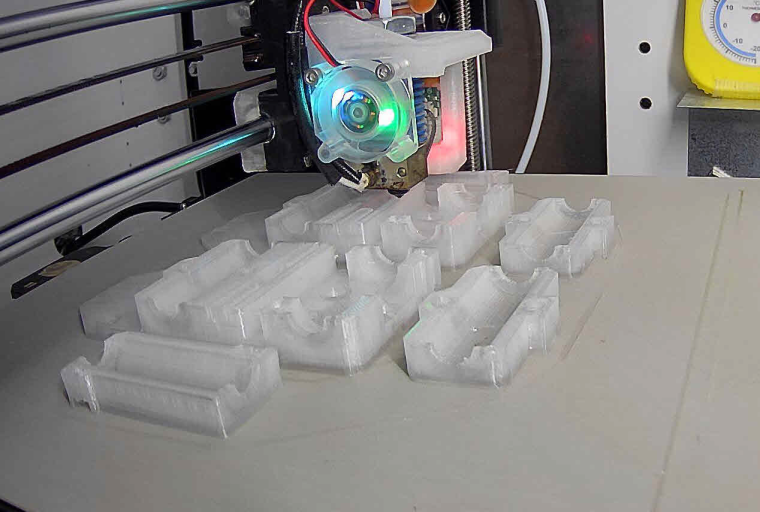

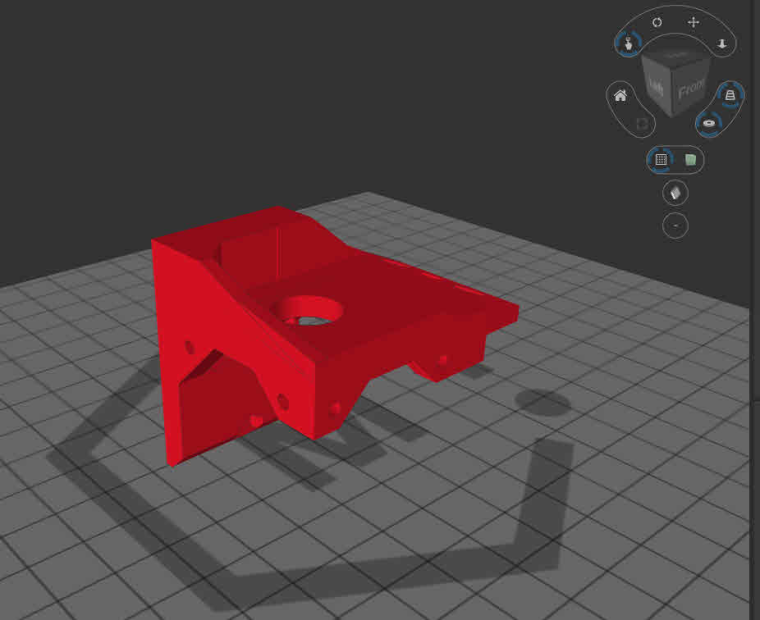

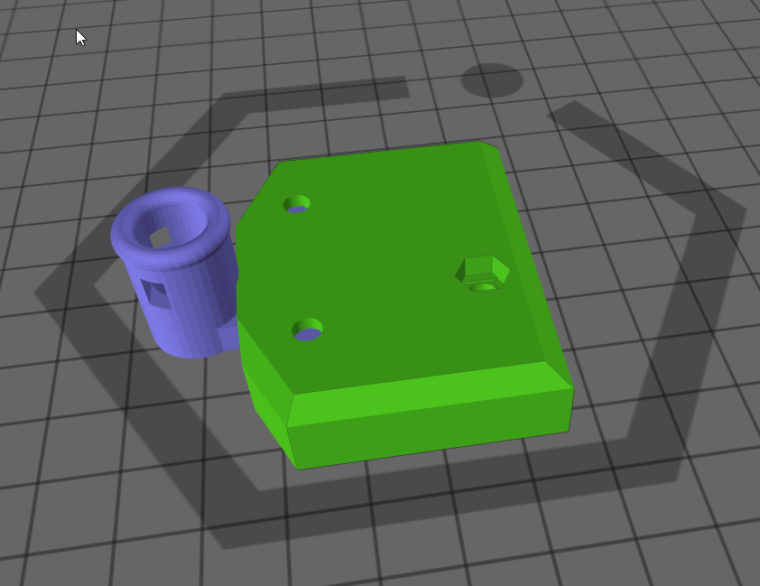

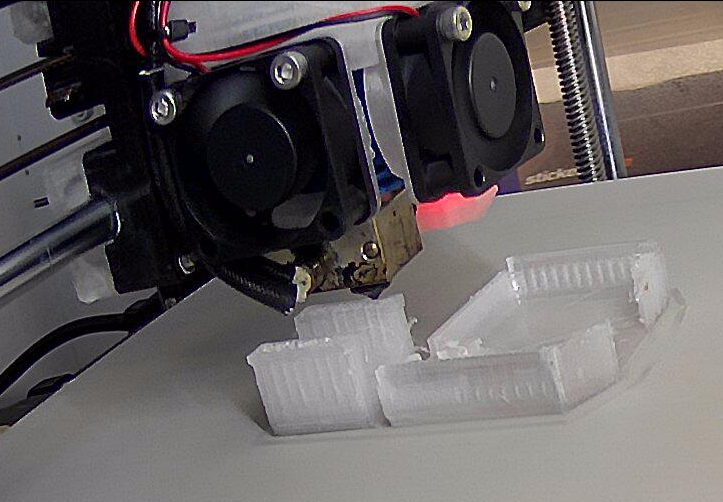

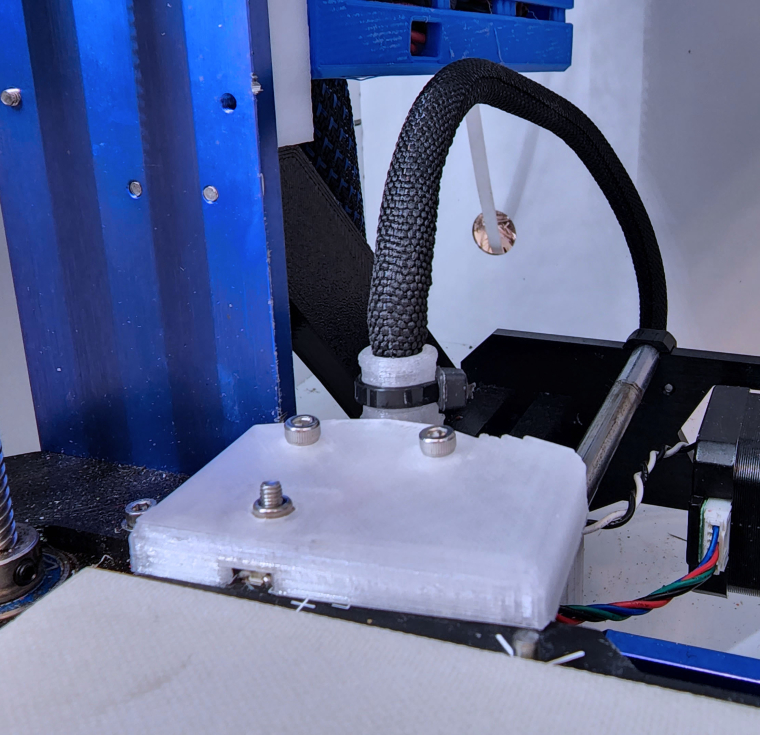

Second attempt to make an ice back plate. The first one cracked when I pressed nylocks into it. This time I adjusted the outer perimeters down ten percent to give a finer detail around the press fit holes.

-

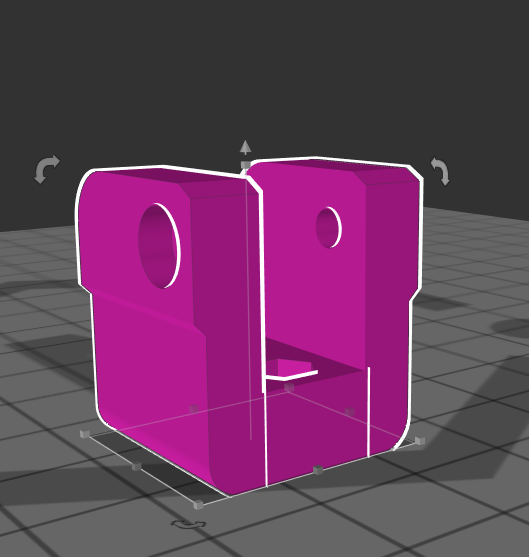

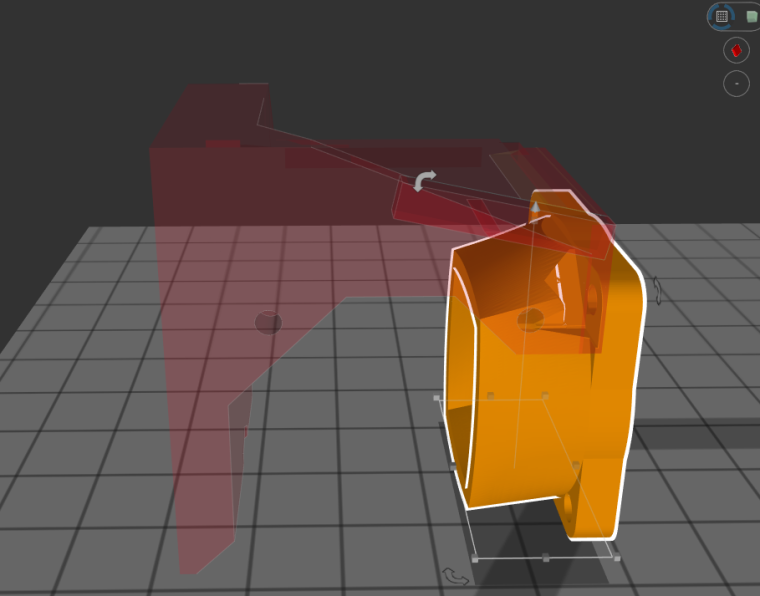

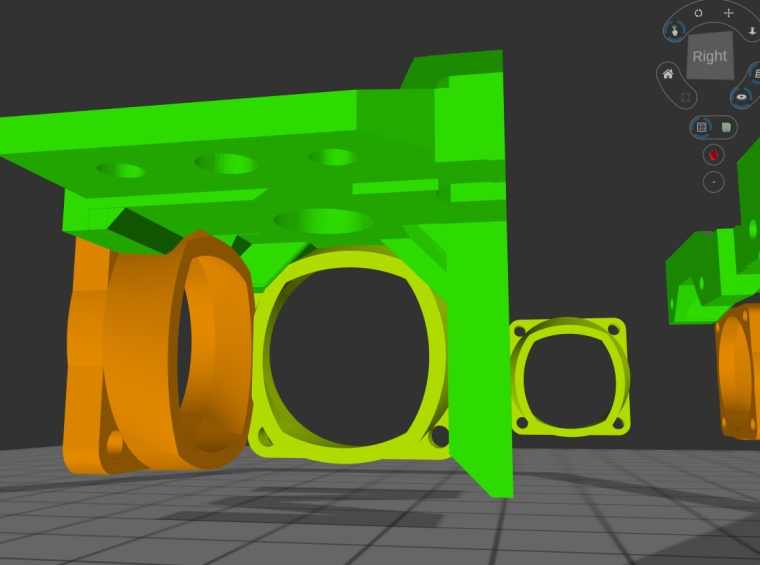

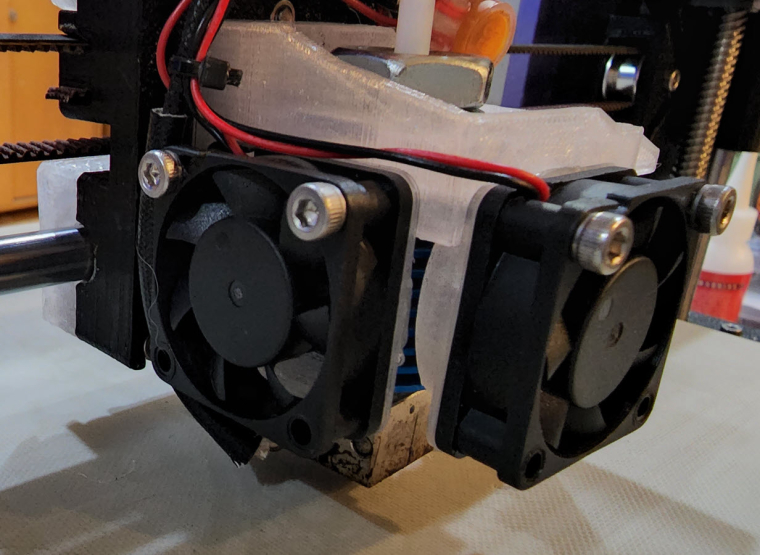

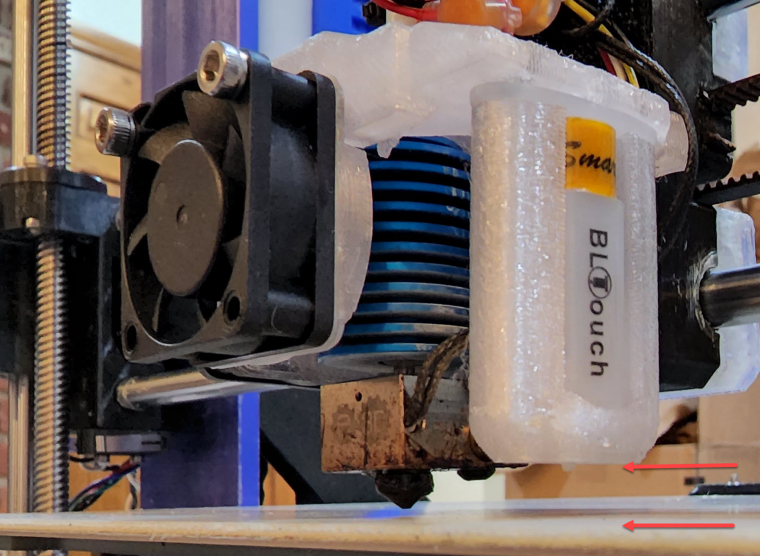

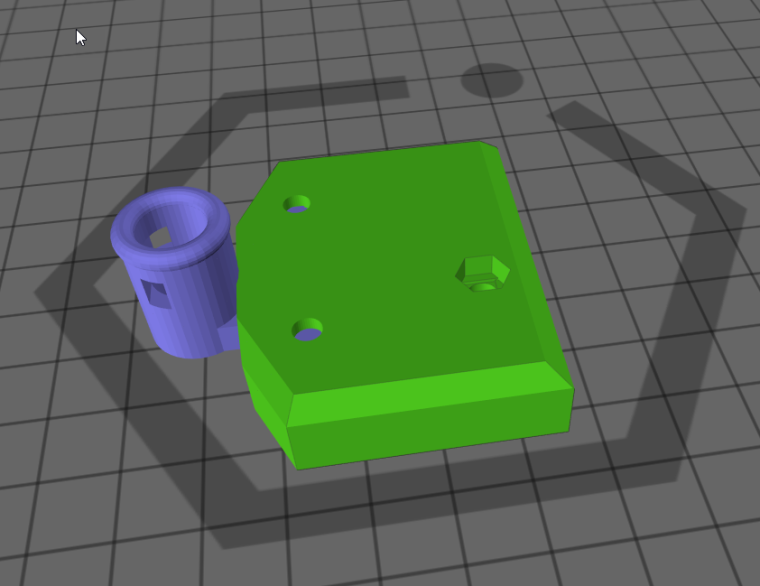

This is a new V6 hotend mount I have been working on. This has redundant cooling fans for the V6 heat sink, doubling the air flow for high temperature parts. I have also raised the BL touch 1mm to provide more clearance, minimizing layer shifting issues.

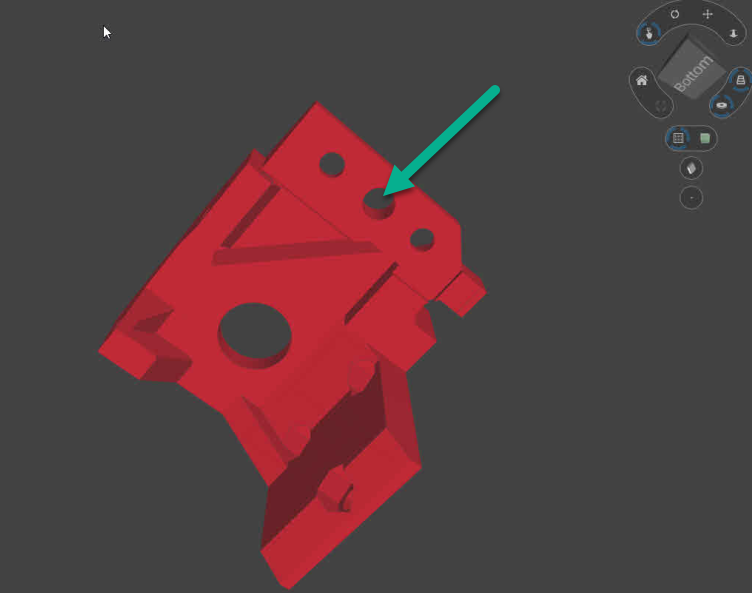

Center hole allows you to fix a broken bltouch needle without removing the whole BLtouch.

-

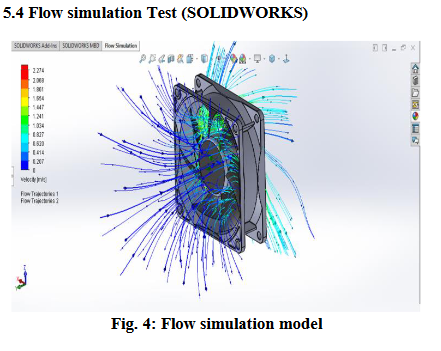

Computer style fans do not blow straight outward, most of their airflow comes out the edges. In order to flow the air straight at an object, an air funnel is needed to direct the flow. I have created two of these which will direct the air to the heatsink and away from the heater block.

-

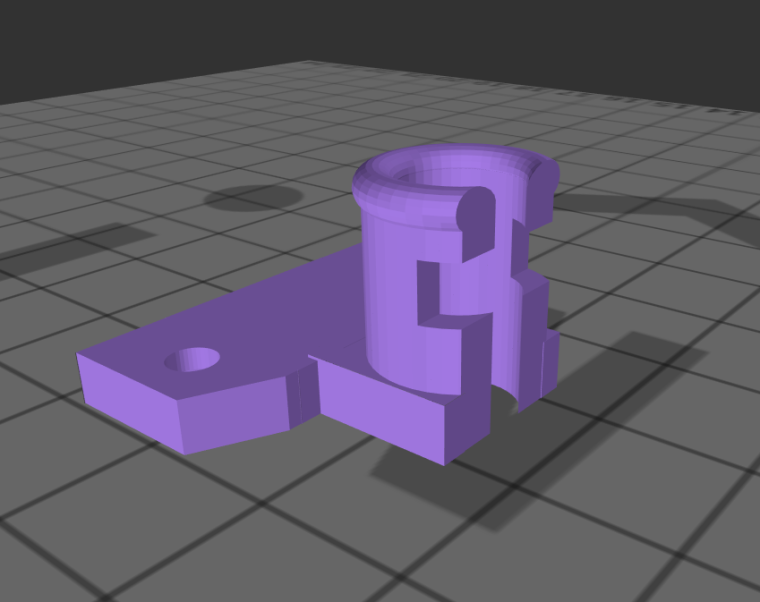

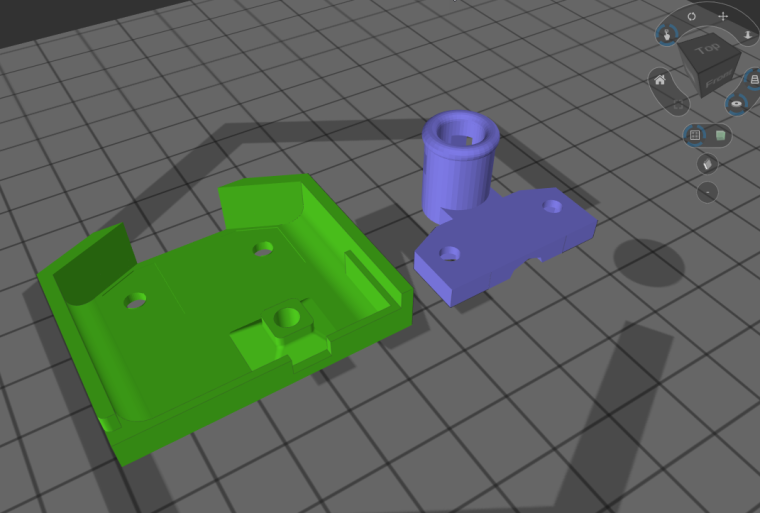

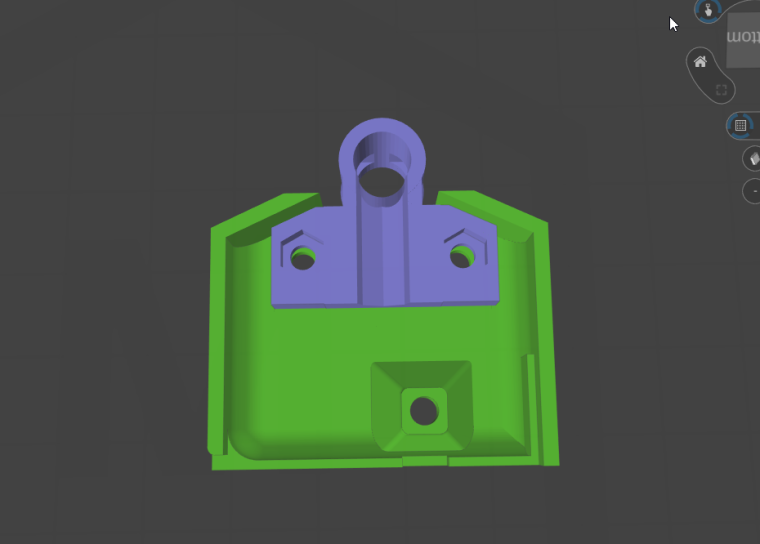

The heat bed cables are constantly coming in contact with my enclosure, only a matter of time until I damage another heat bed. So I decided to create a new strain relief which will protect my cables. It's a two part design so no supports are needed to print. I may need to open up the 90° fitting a little for cables which come in at an angle.

-

-

If anyone wants to try any of my custom parts, just ask in this thread. Some of the parts are MCX only, so you will need to slice them in MatterControl.

-

Air is pushed up and away from the heater block and directed to cooling fins.

Dual 13,300rpm cooling fans, 10.2 cfm. Most 30mm fans are 3 cfm each, which is fine for lower temperature plastics, I have used these fans for petg with little issues. Nylon composites need higher flow E3D fans. The problem I had with the single E3D fan was keeping the heat sink cool with +300°C hotend temperatures. HT 30% glass and HTN CF require 330-350°C which is harder to do in a heated chamber without water cooling.

I have greatly increased the BLtouch clearance from BLArmor to print bed, while still maintaining probe depth. This minimizes contact with print blobs or warped parts while printing. I have even greater clearance than a magnetic probe.

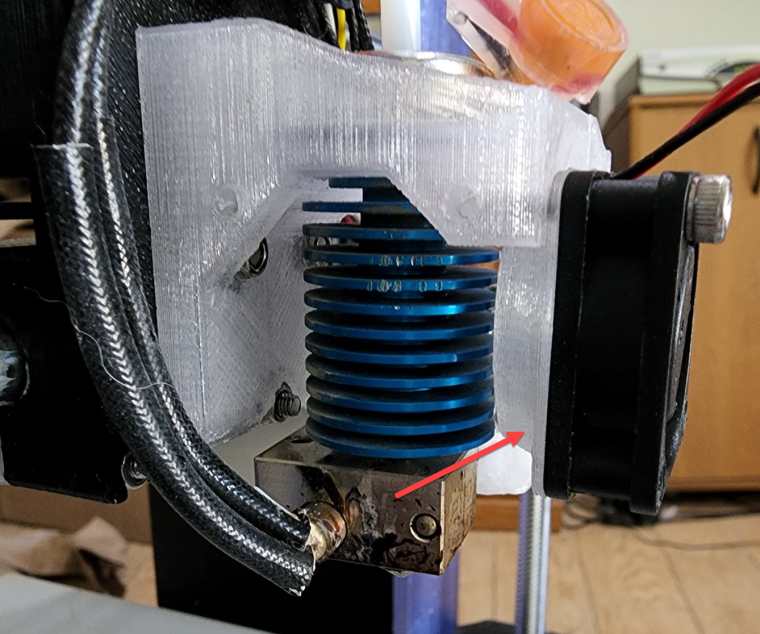

As seen in the image above: E3D threaded heatsink w/SSteel star fastener, 3D Passion titanium heat break, E3D copper heat block, Slice Engineering 50watt heater, pt1000 thermocouple, Diamond tip 0.4mm nozzle.

Tested to 440°C

-

-

I had to go back and make a larger version of the strain relief to fit the new heat beds. Now the bed wiring no longer smashes against the enclosure and will feed into the top of the new enclosure, keeping it up and out of the way.

-

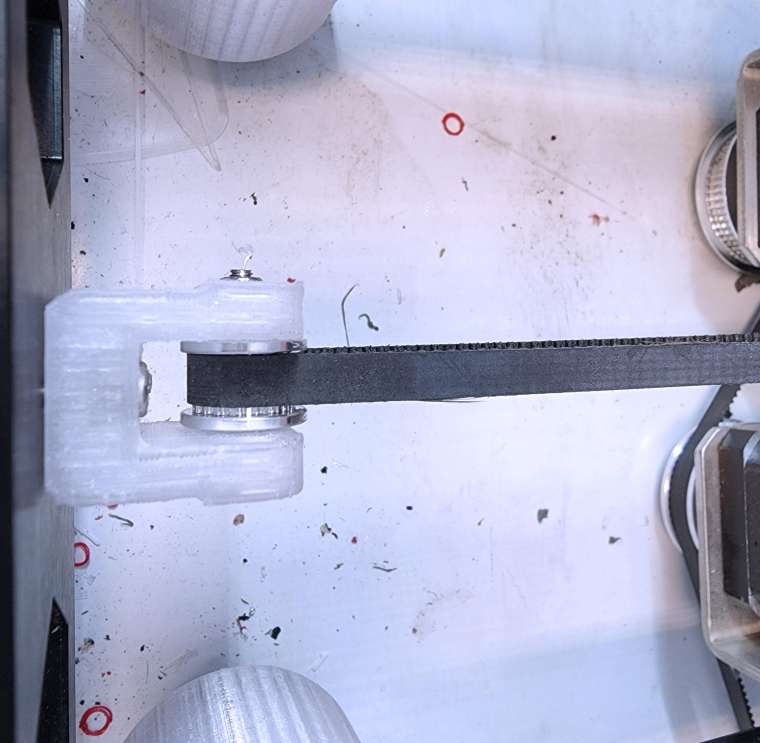

If at first you don't succeed, try, try, try ten times again...

I am not sure why such a simple project took me so many times to complete. So I finally got the idler the correct size with the Gates machined pulley. The original pulley is smooth with a 3mm bolt shaft. You are not supposed to use a flat pulley on the tooth side of belt. I used the M3 bolt, but with a 6mm aluminum spacer. Works perfectly and will keep the teeth fresh.