Working on electronics for the tester

-

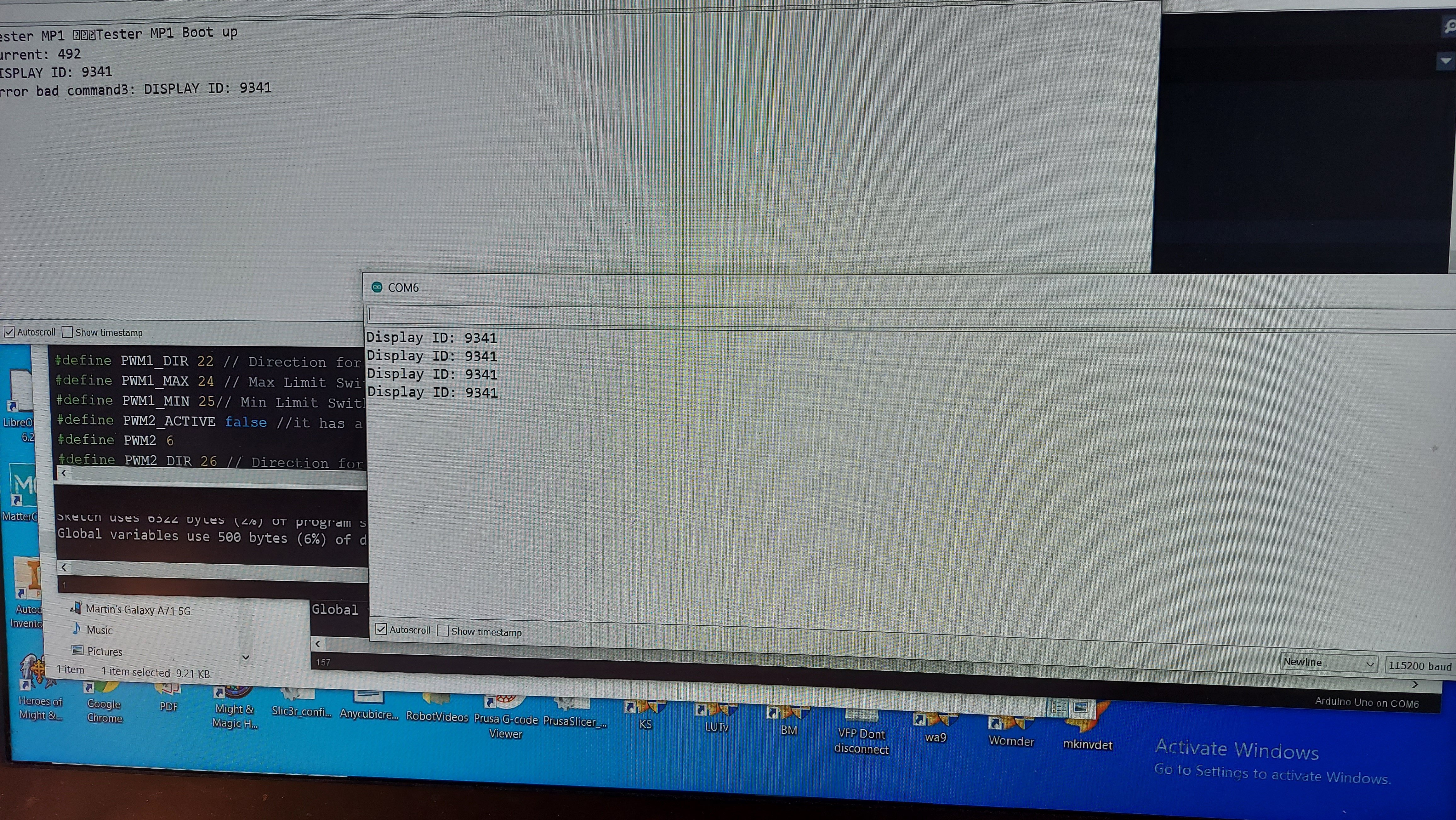

Menu system with a TFT powered by an Arduino UNO. This communicates with a serial connection to a Mega 2560 which does the heavy lifting

for debugging purposes both arduinos connected to the computer

Still to do is to make some electronics boards to current control the 3 motors. that means using them as torque motors as for the tester we are interested in measuring the torque. Each of the 3 motors will be controlled in a range from 0 to 40 Amps. The speed feedback will be via encoder so it can be used as a closed loop system and this is the heart of it

the 128:1 compound planetary

-

@thwclw Thanks I went for the visuals too right now its I think about 4 kg of HIPS about 20 608 bearings and almost 100 nuts and bolts. if you Want your own all the files are here

https://grabcad.com/library/testequipment-2

you wont print it on a pulse though. This one needs a 300x300 bed or larger as the big ring holder are 286mm end to end. I used HIPS cause I pick it up for less than $10/kg and so its less of a problem if you have to reprint something cause it doesnt fit then if you use Nylon

Now this is one you might be able to print on a pulse

The Holder is ABS the gears and Rim Nylon 910 and the tire TPU.

All was printed on a Chiron