PLA Issues

-

I have been away from my Pulse Xe for a while but back at it and decided to take MH Builder's PLA for a spin and having issues getting a clean space guy. I have tweaked my "Z" so I have good adhesion to my Buildtak surface, using default settings from MH for the flow etc.

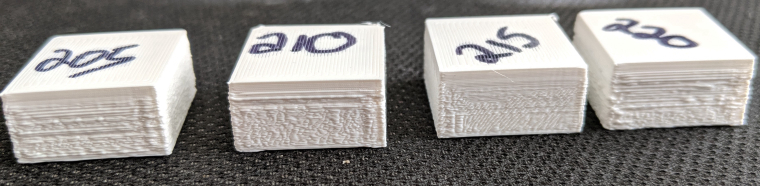

Three attempts after printing a clean "cube" test, the one on the left is 200 deg, middle is 205 deg and the right is 210 deg hot end temp settings. Cooling fan is running 100% during the print but all three have a bad case of "saggy butt".

So what am I missing, besides thinking PLA should be straight forward after NylonG.....

-

ok, lower temp to 190, slow print speed some for test...

try a over hang bridge test ...https://www.thingiverse.com/thing:2972495

you can find me on discord if you need help Zoromer #0532

-

To rule out a hardware problem do a test print with a filament you used before

-

@pverdin said in PLA Issues:

while but back at it and decided to take MH Builder's PLA for a spin and having issues getting a clean space guy. I have tweaked my "Z" so I have good adhesion to my Buildtak surface, using default settings from MH for the flow etc.

Three attempts after printing a clean "cube" test, the one on the left is 200 deg, middle is 205 deg and the right is 210 deg hot end temp settings. Cooling fan is running 100%This definitely looks to be a cooling issue. I agree with Martin though, does this happen with every material? Do you see both fans spin when the part is printing?

-

@zoromer I thought the temp was the cure but no such luck. The latest along with the overhang print out, both at 190 degrees, nothing else has been changed.

-

@mpirringer I will load up something different on Tuesday and see what happens.

-

@erikescudero said in PLA Issues:

@pverdin said in PLA Issues:

while but back at it and decided to take MH Builder's PLA for a spin and having issues getting a clean space guy. I have tweaked my "Z" so I have good adhesion to my Buildtak surface, using default settings from MH for the flow etc.

Three attempts after printing a clean "cube" test, the one on the left is 200 deg, middle is 205 deg and the right is 210 deg hot end temp settings. Cooling fan is running 100%This definitely looks to be a cooling issue. I agree with Martin though, does this happen with every material? Do you see both fans spin when the part is printing?

Haven't tried any other material, both fans are running while printing, I have not experienced the cooling fan before when printing Nylon 6.

-

@pverdin No fan on nylon. You can manually turn the fan on in MC under options I think and see if air comes out by the nozzle. If it doesn't you have a problem. Also make sure that under cooling you got the fan running probably close to 100% with PLA except on the first layer

-

@mpirringer The fan is running 100% on the PLA, not sure how much airflow I should have at the print head though or how to measure other than run it and go by feel.

-

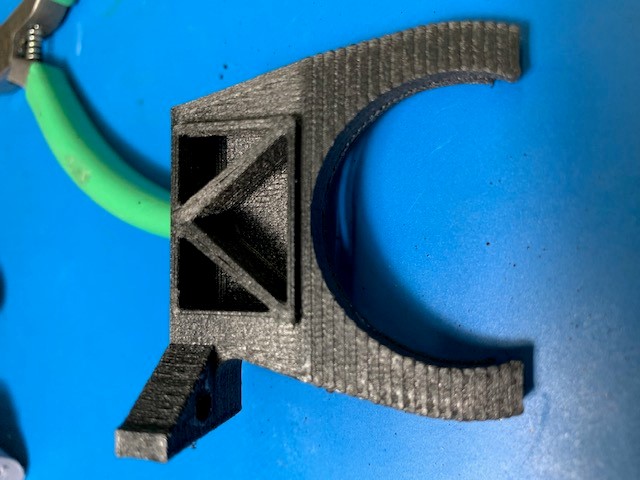

@pverdin Looking at the drawing for part 503 the shroud, it appears to be solid with openings at either end, mine has a gap that goes all around the unit,

-

@pverdin Try to close the gap - You want to direct all the air right under the nozzle where the filament comes out and no where else

-

@mpirringer said in PLA Issues:

@pverdin Try to close the gap - You want to direct all the air right under the nozzle where the filament comes out and no where else

Part of my testing with a different material today will be printing a new shroud, probably from Rhino. Thanks for the response.

-

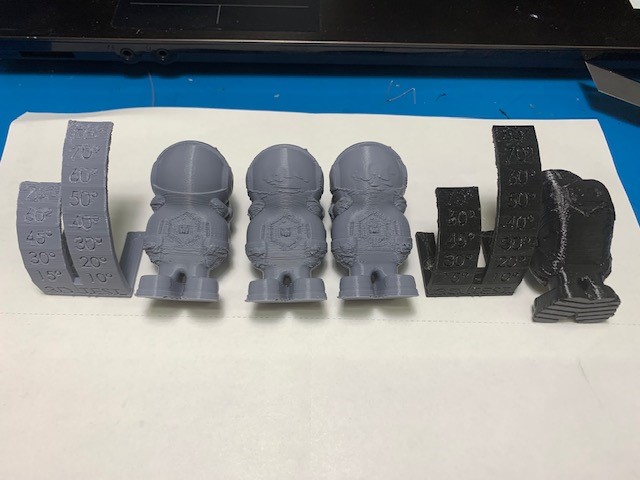

Changed material to Rhyno (black) looked fairly clean, I suspect some moisture but still a cleaner print. Changed the cooling shroud and printed the middle two grey guys, still wrinkle butt but now wrinkle face. The far left guy I printed with both doors of the enclosure open.

On the back side, same old butt issues two different fan shrouds tested and again the far left one printed with doors open.

Not sure what the next step, would like to print with PLA for simple economic reasons.

-

For economic reasons HIPS and ABS are cheaper than PLA in many cases and you do not need a fan. From what I see I do think you have cooling issues. YOU can raise the nozzle and put a cup of water under it and lower the nozzle over it so its about 5 mm above the water. If you turn the fan on then you should see a "dimple"depression and some circular waves ideally in the cup with the center under the nozzle. If you don't you might have a fan that does not give you full power or you could also have a break in the wire where it makes enough contact when it holds still but not when it moves as the contact turns on and off. The thing in MC tells you how fast you are telling the fan to turn and not how fast or if at all it actually turns

-

I don't understand all of this, I have never had a fan attached to my printer and do not exhibit any of these problems, with either PLA or PetG.

-

@erniehatt All printers have a fan. PLA needs to cool quickly hence a fan. Most materials need one on bridging. Some like nylon hate fans or even little drafts. So if you want to print PLA you have to have your cooling right or you get lots of crap due to the filament staying soft too long especially on small prints as its still soft when the next hot plastic noodle comes along and your print will look like you tried to make it out of well cooked spaghetty. Its because PLA has to be cooled below 60 or so to have any structural integrity. Whereas Nylon for example is mechanically sound at about 160 C and if its too cool and not still "tacky" then the next layer cant adhere properly. 3d Printing - there is a lot to learn

-

well I built and rebuilt 3D printers, and CNC's, over the last few years, and have printed all the necessary parts out of PLA or PetG, with no fan and they turn out fine.

I grant you that if I try to print say a spire on a church model then that possibly would be a problem, but generally not, but that said I print everything with solid infill, that may make a difference.

-

@erniehatt PETG does not like a fan. And if the part is big or you print multiple parts then you dont need a fan as by time the nozzle comes around again the filament will have cooled down sufficiently

-

I get the same issue on my pulse with white pro series PLA. NylonX looks amazing with anything I print. Wanted some color so I bought pla pro white. Lots of sags and layer lines.look bad.

-

I get this with fan on as well.

I get this with fan on as well.