Solex Ruby nozzle

-

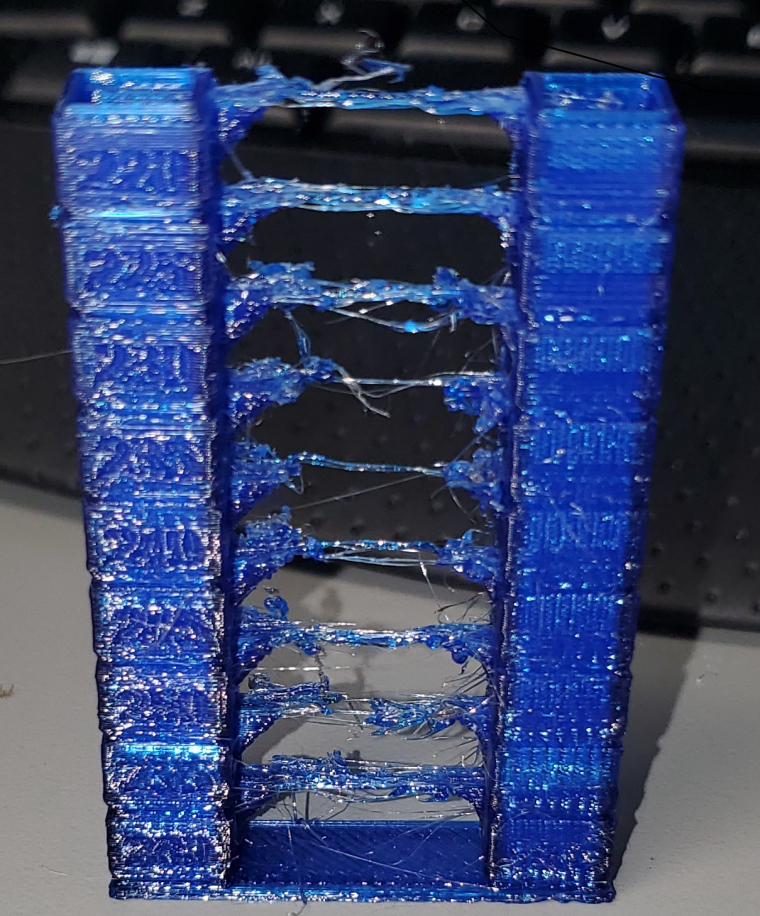

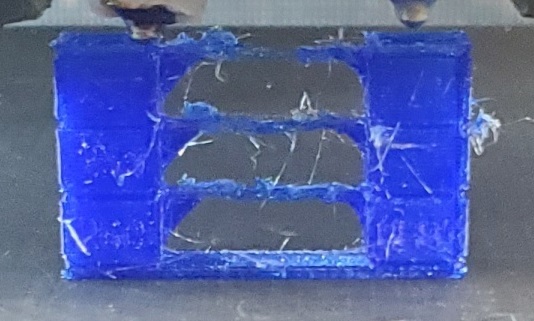

I just installed a new 3D Solex Raise3D Pro2 Everlast Ruby Nozzle - 0.40mm

and i cant seem to get the bridging to print cleanly at all with petg. I haven't tried other types yet

Does any one have any ideas on that is wrong i havent had this issues until now

-

Looking at the photo, it definitely looks to be related to your cooling. Does this happen with every material or just PETG?

-

So far. I mostly run PETG and Nylon in my office. I tried loosening the fans a bit this morning and things are looking better i will try to print new shims today and see if it helps

-

so i tried pla no issue its only a issue with petg like if its balling up on the end of the nozzle

-

Petg in general does not bridge as well as pla and some petg really hate the fan so sometimes instead of going slow with fan going fast with no fan is better (not good but better)

-

I think your problem is NOT PETG but rather printing in general.

Entire print all around looks like crap and you expect it to bridge nicely ?

Good luck with that.After years of printing i made up one rule:

Rule #1 If you cant get 1st layer perfect, dont bother printing the rest.

Rule #2 Obey Rule #1Your prints look like crap at 1st layer, why do you even continue with the test ?

My PETG prints came out better then ABS or PETG.

With little FAN it makes it look even better.