Print problem

-

This problem has just arisen.

Dimensions in general are pretty spot on, except for holes, they are turning out much smaller than designed, and very egg shaped rather than round, any suggestions on the cause. Thanks.

-

Print a top open box so you have no infill with a known wall thickness let say 2mm thick then measure it and adjust your extrusion multiplier and slice setting based on measurements of the wall thickness with a caliper. An oval vertical hole is usually a sign of over extrusion. Also note that without support the top of the hole might get flattened and/or have droops Laying down holes on the build plate might suffer from "elephants foot". If your holes need to be absolutely positively dead on print them a little smaller (0.2mm or so) and add an extra perimeter and then use a drill press and a drill bit to make it sized properly. but for clearance holes for bolts getting your extrusion right is usually sufficient

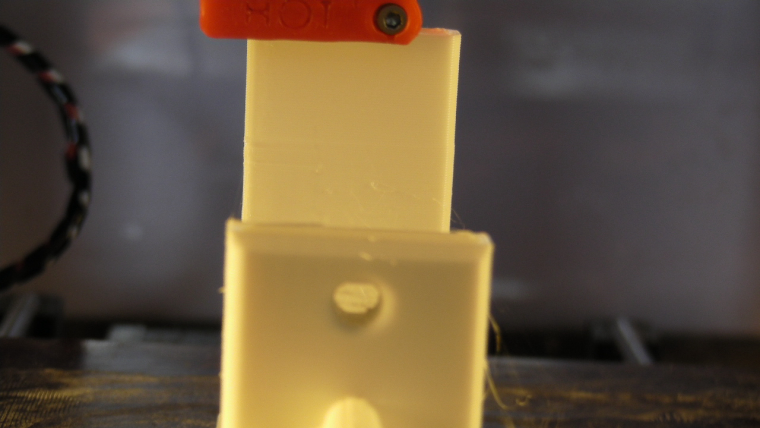

This is currently still printing the flat spot on top is cause its being printed with a .48mm layer height (.8mm nozzle) .But its a clearance hole for a 1/2-20 bolt and so sized at 6.8mm and that little flat spot is figured in and does not matter. Sorry for slightly out of focus but lighting is bad and the thing is moving on the printer

-

Thanks for the reply, As you say add perimeter I always use four, the big concern was the shape, I will try what you say.

-

Where do I find these error codes, and what do they mean.

-

That error code response was spam. Sorry about that. The account has been deleted.

-

Thanks Lars, appreciated.