Pulse XE X-Axis Tensioner Mod

-

Summary

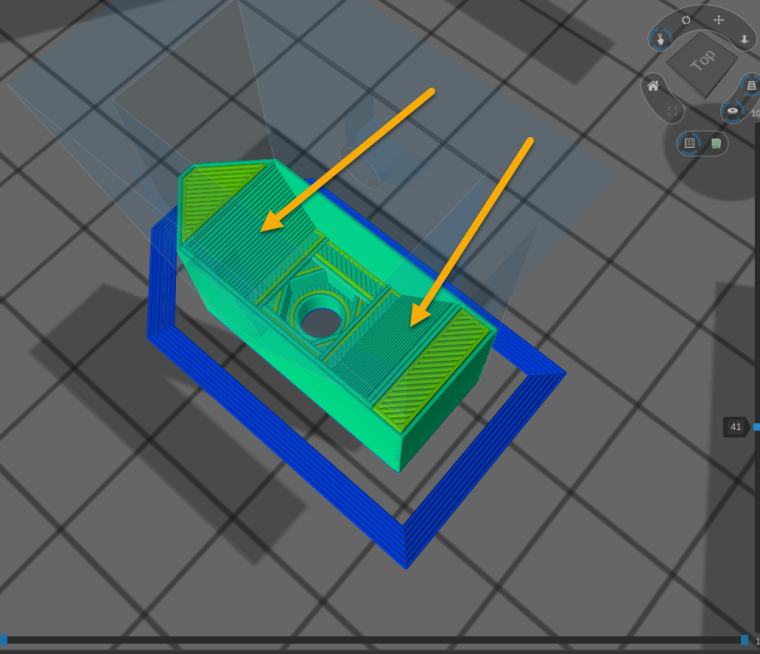

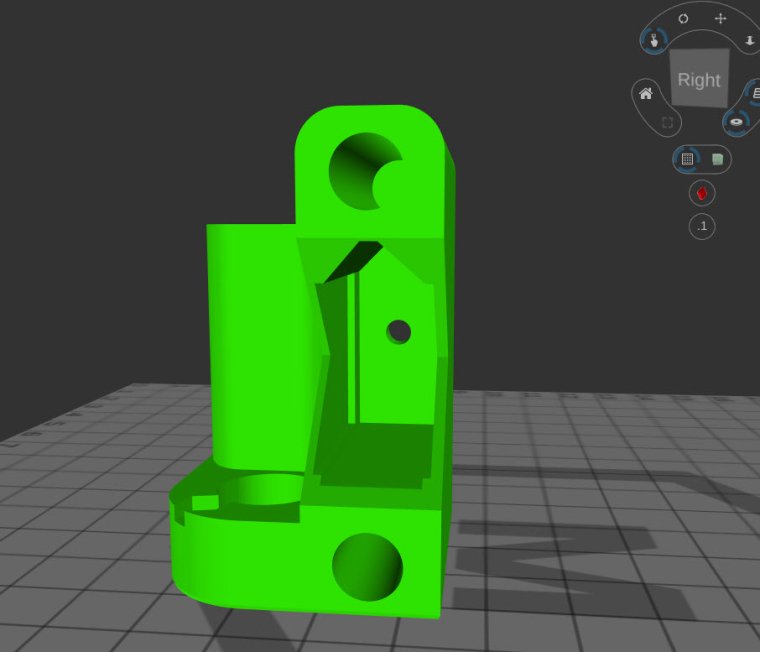

After having my x-axis tensioner snap in half during the middle of a print, I redesigned the tensioner and printed a replacement. The two ramps where the yellow arrows are have been added to increase strength near the pull force. This also reduces the bridging needed at the top. It was in this location that my original part separated. This will no longer be an issue.

There is nothing wrong with the original design, it just needs to be printed with 100% infill to increase it's strength and prevent the issue I had. For this reason I have included both files.

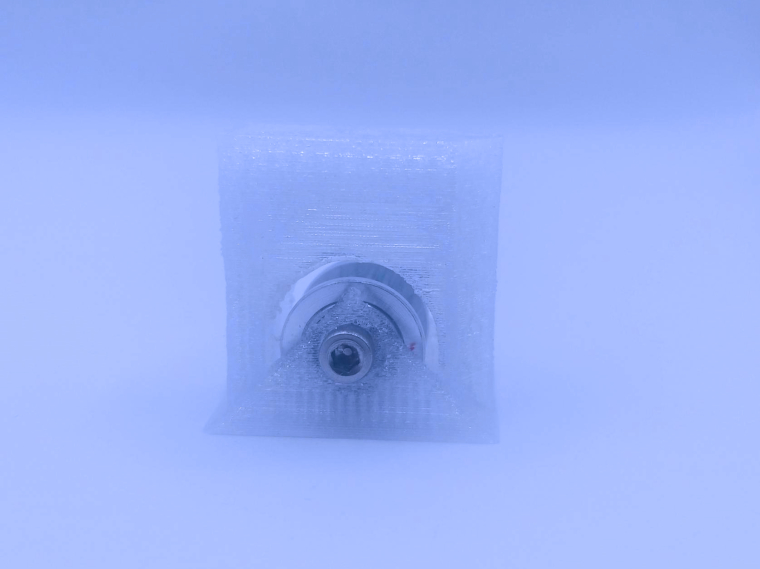

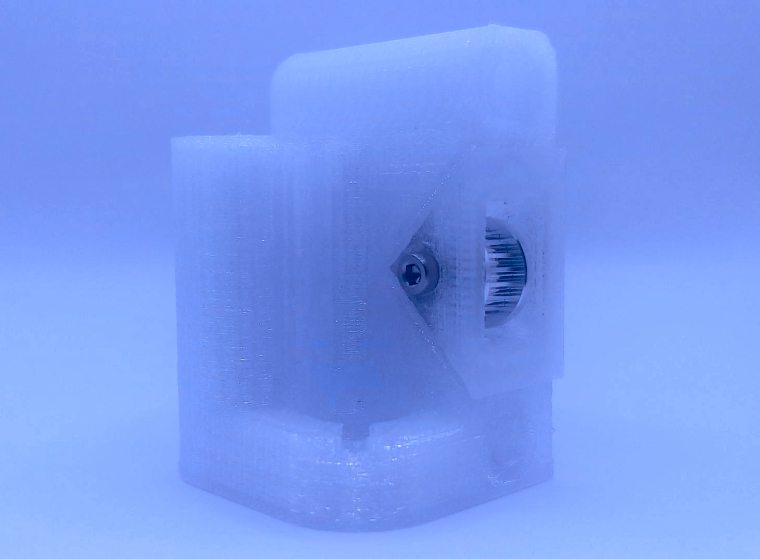

Note: You can print this in petg, polycarbonate, nylon, etc. I had peek loaded at the time, so that is why my part looks kind of janky. I will probably reprint in polycarbonate later. Also, I used a 40mm long M3 bolt to set the nylock in place. I used Gel super glue to set it in place. This will greatly help when you assemble the tensioner on your printer.

Print SettingsPrinter:

MatterHackers Pulse XE

Rafts:

NoResolution:

0.30Infill:

100%Filament brand:

MatterHackers

Filament material:

PETG, Polycarbonate, Nylon

Print Files Here

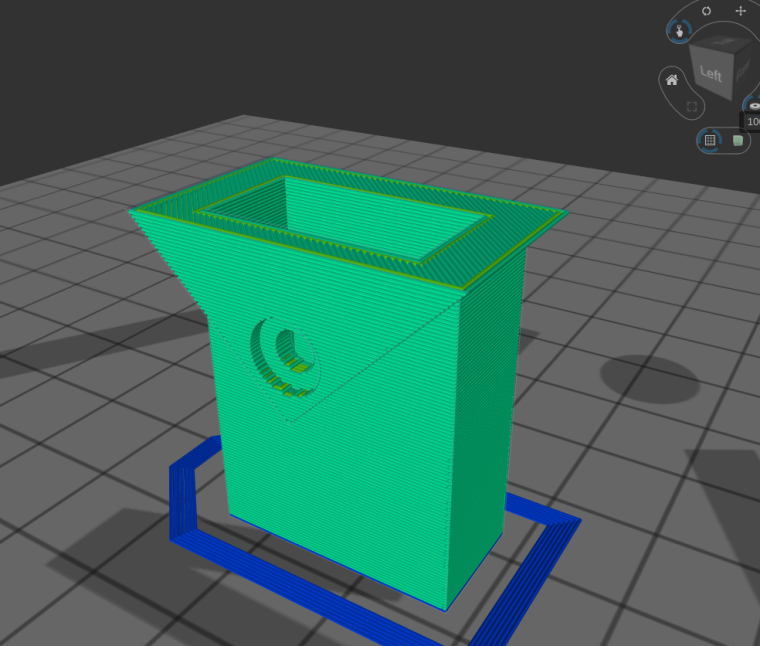

And also hereThis is upside down on the print bed for reference. Flip the part 180° before printing.

-

You can print this @25-35% infill and it will be strong enough. I increased the top solid layers to 3mm. This makes the top solid for strength where the lock nut is pulling against the whole back end of the tensioner.

-

@tinken will the I.D. accommodate a gates 20ttothed idler? i know the one on my machine is just a hair too narrow.

-

@csenior10 The ID is not the problem, the Gates pulley is too wide.

-

Misumi sells some high quality idlers.

-

@csenior10 Prototype modification for Gates idler in the tensioner. I will have to modify the motor mount idler side as well.

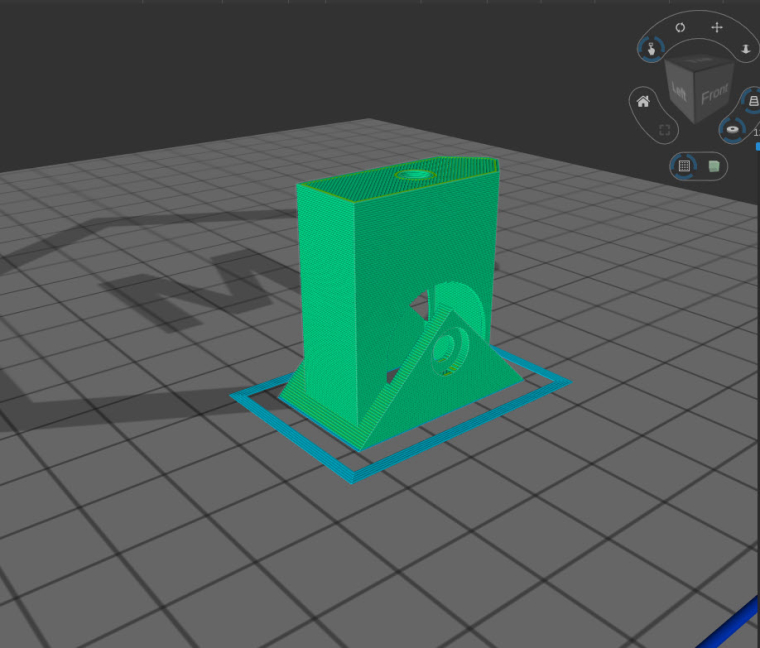

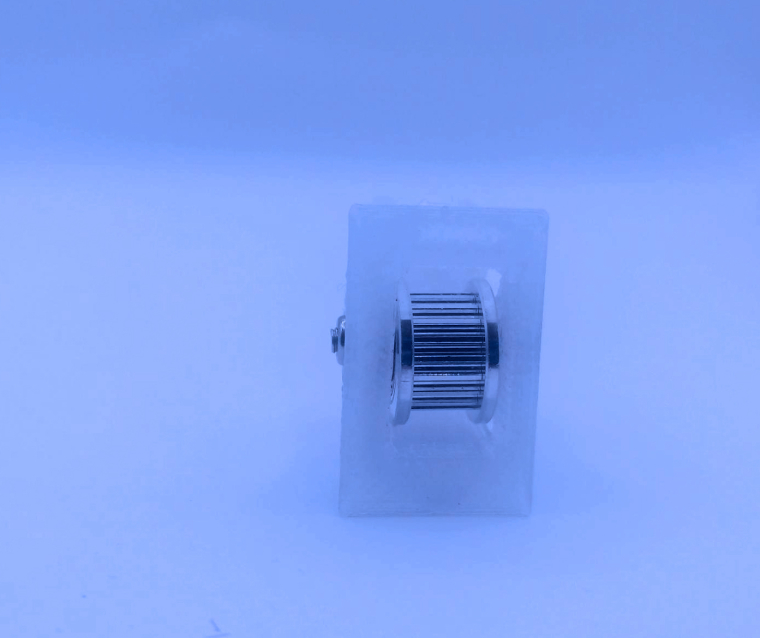

I wasn't sure if this needed supports until I printed it. Supports are optional, my part printed better without them. Gates pulley requires a M5 bolt, however, I suggest sourcing a spacer instead. 3mm x 5mm x 10mm. !

!

-

I have modified the x axis motor mount idler to fit the new tensioner and Gates pulley. Also, when printing these motor mounts, it is recommended to have an 8mm reamer to adjust the linear rod holes.

-

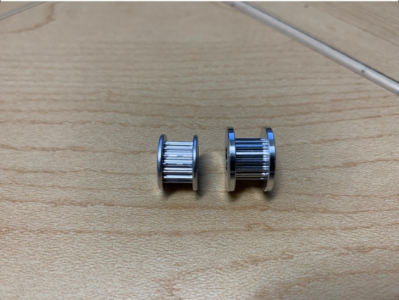

These are 9mm pulleys. The one on the left is Chinese made. The one on the right is made by Gates.

-

Even if you don't use the Gates modified tensioner, I am finding that the modified x-axis idle side bracket slides nicer than the original one with the original tensioner. I used a 8mm straight ream in the linear rod slots and they fit nice at snug.