First layer issue

-

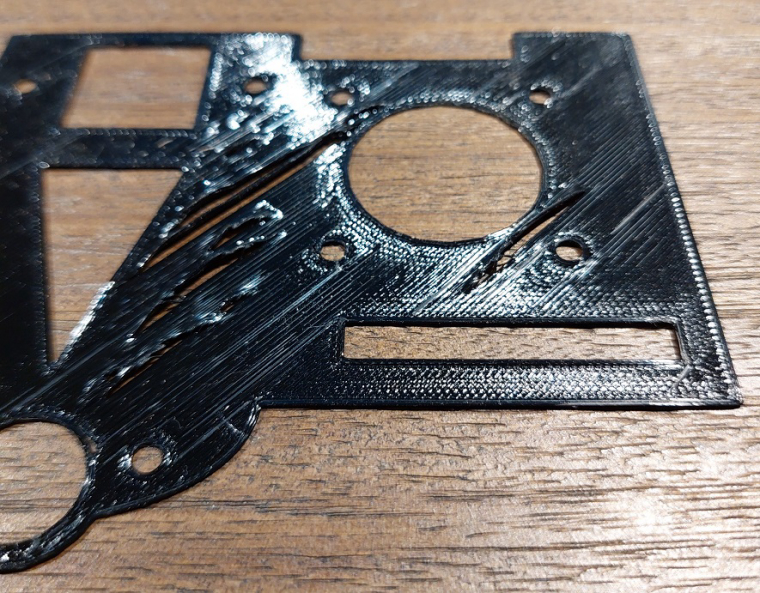

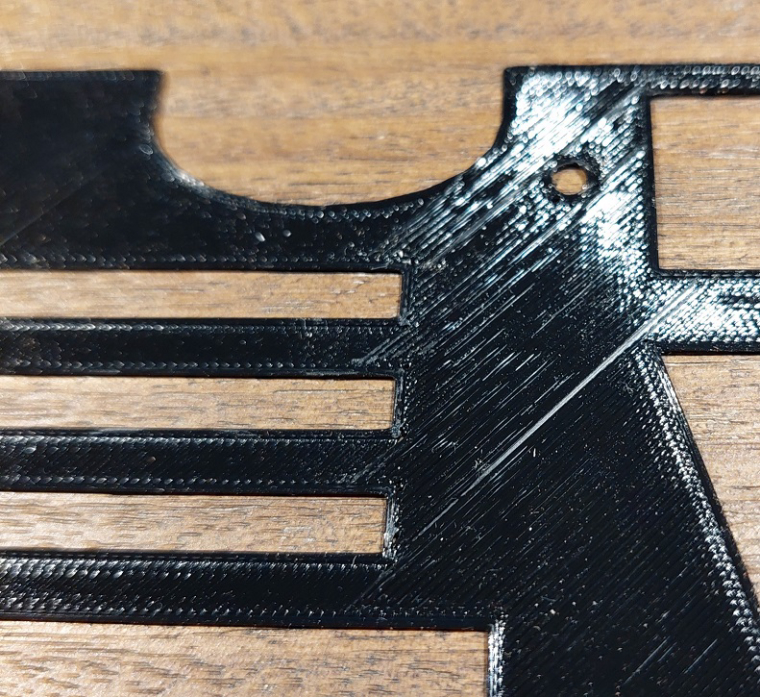

I've had my Ender-3 for a little over a year and have been using Matter Control for about 8 months. That being said I still consider myself a novice because I've only been printing in earnest for the last month or so. Most of my projects have been small but I have noticed the occasional missing line (short segments) of filament and I kind of ignored it because for me it was more cosmetic than anything. Today I tried to print something bigger and important (for a project I'm working on) and you can see the areas where consecutive runs of filament aren't bonding together and started to curl up away from the print bed. I think (because I'm still very new at this) that this is under-extrusion but I'm not sure. If it is, what would be the best way to address it? I'm using Overture PLA+ with the hot end at 215 and the bed at 65. I haven't really had problems with adhesion until now (I have a glass bed and I've been happy with it), but I would like to get this figured out. I was able to finish this print but the face, which is usually smooth as glass, looks a little chewed up. I appreciate any insight you all may have.

-

What is your first layer speed?

This doesn't look like underextrusion.

Printing straight on bare glass can be a little tricky with bed adhesion. It may be something as simple as a fingerprint or 2 in the wrong spot that makes the PLA not adhere to those areas.

-

@cope413 I recently started experimenting with PrusaSlicer and I noticed that my Ender 3 is printing a lot faster. I had shown these pictures to a couple of folks that I have purchased 3D printed products from and they basically said the same thing you did. I just looked at the settings in PrusaSlicer and first layer speed is set at 30mm/s and the first layer height is 0.35mm. For reference, the same settings in M/C are 20mm/s and .20mm respectively. I wanted to try PrusaSlicer because James Fewster, who prints commercially, had high praise for it. One of the things I noticed is that an STL file exported by M/C and then imported into PrusaSlicer reports the there are various errors that need to be fixed (which it does). I re-slice and export the file as Gcode, then open that Gcode in Matter Control and print it (a bit involved I admit). It seemed that, overall, I was getting better prints, except when there was a large first layer surface area as in this item. Based on your suggestions I think I will go back to this single layer test print with the slower and lower settings and see if it makes a difference. As to your second point, I do thoroughly clean the build plate with IPA between each print (looking for fingerprints) and they are generally stuck on there pretty good. Thank you for your response.