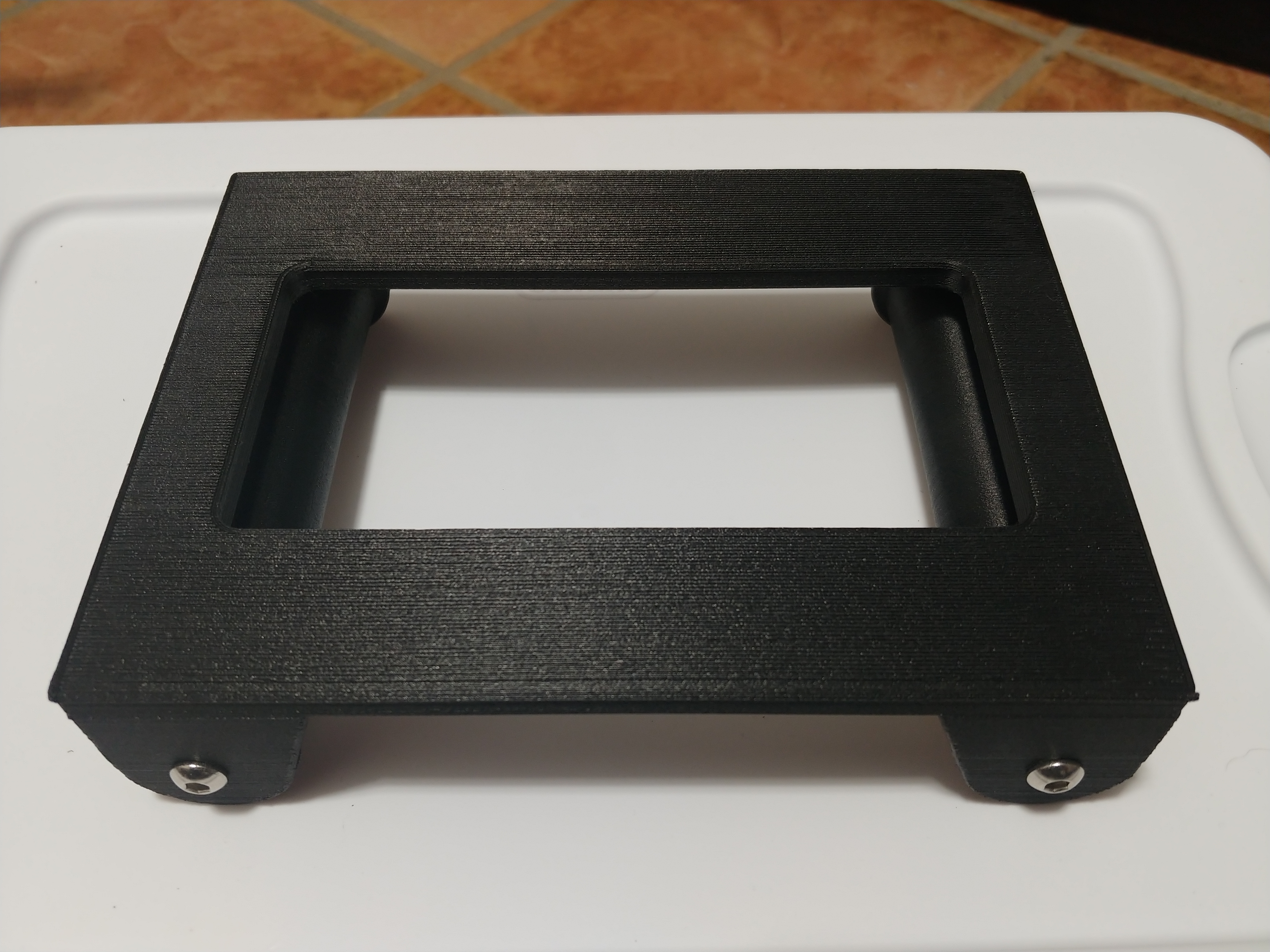

My Spool Roller

-

Interesting spool holder has concentric rollers to keep the spool always in the center of the roller.

Printer:

MatterHackers Pulse

Rafts:

Yes

Supports:

No

Resolution:

0.2mm

Infill:

30%

Filament: MatterHackers Pro Nylon Carbon Fiber Black

Notes:

This is a nice design, I printed up several of these in carbon fiber for strength and heat resistance in heated sealed boxes. Low suggested infill caused shrinking of the base plate, boosted to 30% with hexagon infill made it stronger. Nozzle 260C, Bed 65C, Chamber 35C.

Some constructive criticism: For a one piece design, the base is too thick, it should be no thicker than the uprights. The uprights need front and rear bracing added to the design for strength. The concentric rollers are beautiful, but the bearings used are less popular and harder to find than 608 bearings.

A few remix ideas:

+Keep base at current thickness, except split into two pieces and add mortise and tenon joint to put the two together.

+Increase base width to match the length, increase roller length to match. This will allow 5Kg spools.

+Add 0.250" bridge between uprights for strength.

+Add triangular or hexagonal holes into the base to reduce filament consumption while keeping strength.

+Increase roller openings to accept popular 608 bearings at each end.

+Modify base uprights to have printed bearing center shafts and remove metallic hardware.

+Add circular indents to bottom of base for adhesive rubber feet.About me: I am the CEO of Tinken Inc. We are an Engineering/Architectural consulting and manufacturing company. I have a Masters in Engineering.

-

Wow, that looks fantastic. I love the way carbon fiber filament prints. It has such a clean surface in addition to its material advantages.

Thanks for sharing.

BTW, I'm planning to add your request for multiple brim layers to the next release of MatterControl. Thanks for all your constructive requests and support.

-

@intj123 Which filament dryer do you use?

-

Anything Nylon needs to be ridiculously dry. I use a commercial convection lab oven set to 85C. I dry my Nylon for 5-7 days. To keep my spools from melting or distorting, I use stainless steel spool supports. You can find my supports on Thingiverse.

-

@intj123 Glad to hear that is working out for you. I am sure if you are a hobby printer, you can get away with a lot.

Unfortunately, it does not work that way for me. I have been manufacturing plastics for over 40 years. I work with many different types of plastics and I have pioneered in this industry. It depends on the quality you are looking for. My plastic parts work under extreme pressure. Some of the plastics I work with have to be heat treated for 10 days at 500°C. What I do is not mythical. Nylon must be extruded very dry and with no moisture or you will have steam at the extrusion die and that can cause irregularities and weakness.