PLA Issues

-

I don't understand all of this, I have never had a fan attached to my printer and do not exhibit any of these problems, with either PLA or PetG.

-

@erniehatt All printers have a fan. PLA needs to cool quickly hence a fan. Most materials need one on bridging. Some like nylon hate fans or even little drafts. So if you want to print PLA you have to have your cooling right or you get lots of crap due to the filament staying soft too long especially on small prints as its still soft when the next hot plastic noodle comes along and your print will look like you tried to make it out of well cooked spaghetty. Its because PLA has to be cooled below 60 or so to have any structural integrity. Whereas Nylon for example is mechanically sound at about 160 C and if its too cool and not still "tacky" then the next layer cant adhere properly. 3d Printing - there is a lot to learn

-

well I built and rebuilt 3D printers, and CNC's, over the last few years, and have printed all the necessary parts out of PLA or PetG, with no fan and they turn out fine.

I grant you that if I try to print say a spire on a church model then that possibly would be a problem, but generally not, but that said I print everything with solid infill, that may make a difference.

-

@erniehatt PETG does not like a fan. And if the part is big or you print multiple parts then you dont need a fan as by time the nozzle comes around again the filament will have cooled down sufficiently

-

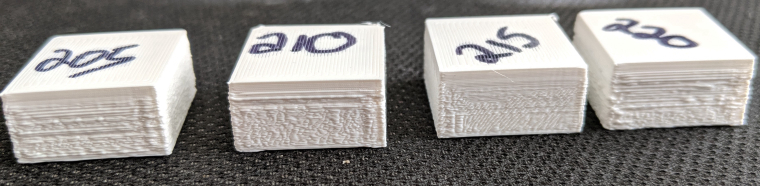

I get the same issue on my pulse with white pro series PLA. NylonX looks amazing with anything I print. Wanted some color so I bought pla pro white. Lots of sags and layer lines.look bad.

-

I get this with fan on as well.

I get this with fan on as well.

-

@mpirringer I did do this check and dimples appeared in the water, on either side of the nozzle it seems. Ran out of time and went back to Rhyno.

Still not sure why the cooling is an issue, but will try again soon.

-

@erievon Looks familiar, not sure what the fix is.

-

This post is deleted!

-

@pverdin That means you are blowing air everywhere you don't want it next to the nozzle and most likely at the nozzle. So you are not cooling the filament and the prints above look like pla with cooling issues. This is one reason I will redesign the hotend and fan mounts. Or maybe someone else got one that works and we can use that. Its not a high priority item for me as I print PLA so rarely and I got a Chiron too which does a nicer job on PLA than the Pulse even with the crappy stock fan mount and there good ones exist on thingiverse

-

@mpirringer Thanks, I will look on Thingverse and see what I can see, I have put PLA on the back burner for now.

-

@pverdin Good Idea. Was printing some prototypes today and for that I usually use filament that I either bought very inexpensive or got for free. It was a reasonably large part - going through the iterations - About 1/2 kg of Filament. So one iteration I printed in Hobby King ABS that I picked up for 4.87/kg looked real nice except its a hideous color. The Other was a spool of Free Prusament PLA I got at the ERRF 2019. That warped all over the place. So I will also stay away from PLA.

-

Hi all,!

First post from a first time owner. I have a Pulse XE also and was experiencing this same issue with my Phil prints. Tried different extruder temps and my Phils look like they've got saggy butt/cellulite and his hands are just a mess. I am waiting for other PLA spools to try. But in the meantime, is this the nature of printing PLA with an XE? Should I just focus on printing PETG and Nylons with this printer?

Thanks in advance and I hope to be able to learn enough to add some benefit to the group!

RJ

-

@rjderama As you can see I too had issues with PLA and never did solve them, but then I found my nozzle leaking internally and had to rebuild my hotend.

I have been using PETG with great success now and it's been over 6 months, I have not gone back to my PLA again because why mess with success.

-

@pverdin Fully agree guess that is why I am currently running through about 10k of HIPS/week

-

Thanks for the help on this. I posted a reply stating II found my solution in using an existing filament profile instead of just winging it. Don't know where it went, but I'm sure it's floating somewhere here.