Brittle PA-CF prints recently

-

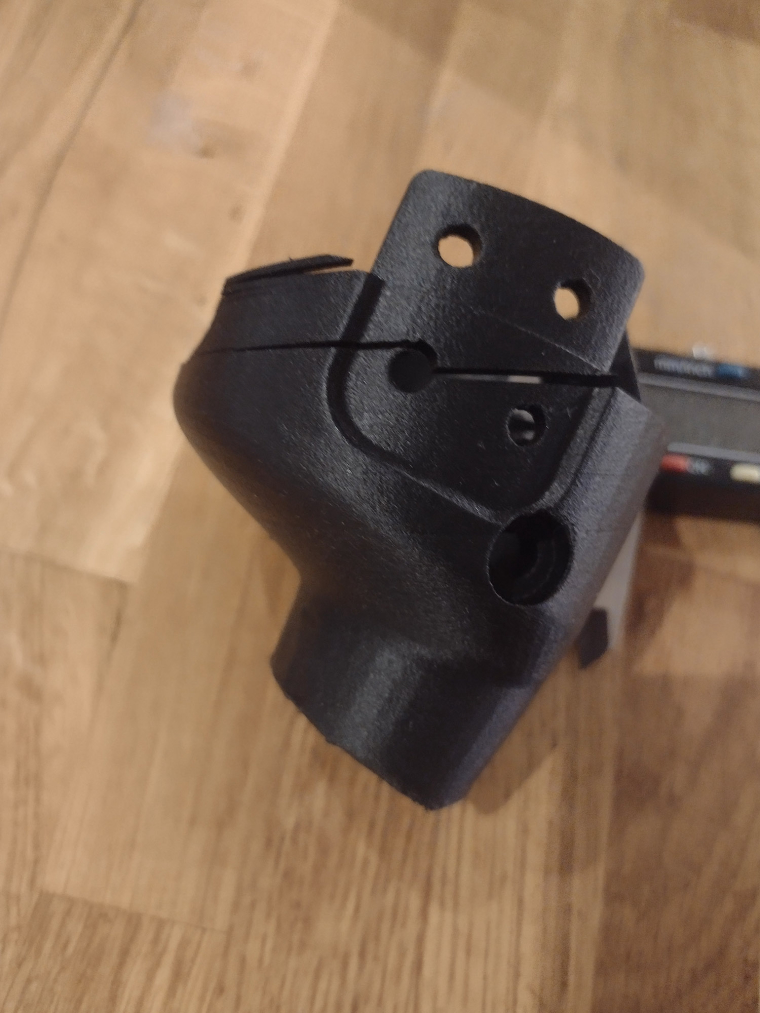

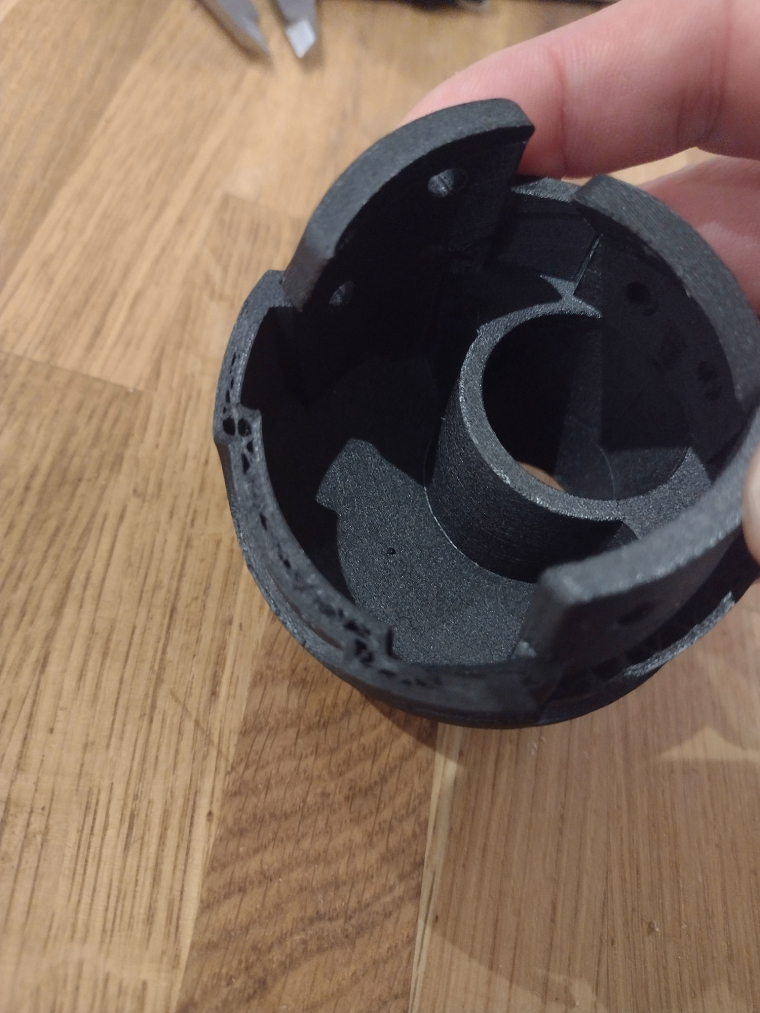

Hi! I have been printing really nice prints with my PulseXE. Almost always printing with PA-CF. Good adhesion with Elmers Purple glue stick. No warping. Parts fitting good so prints exact as the 3d model size-wise. But I have had 3 days of disastrous prints. 3 large long prints. 14hrs + prints. The problem is they look great but are extremely brittle. I was printing great with Fiber Force Nyl Force Carbon Fiber. Not super smooth but Strong parts and no warping. Then I ran out of this filament but I had an old big spool of Matterhackers pro series carbon fiber (previously printing great with this one). It had been opened and not used for a while and so I kept it inside the print enclosure while printing other stuff and the printer has been printing continuously for days so I think it is very dry inside. Anyhow, I printed a long print and it looks super nice. It released easily from the bed the next day but it was super brittle as I was examining it. The print broke easy. I received 2 new spools of colorfabb low warp Na-CF. As they were in a vacuum package I decided to try them so I swapped out the large spool of pro series to the colorfabb. I printed a 17hrs print and the next day it also looked super smooth and nice. As I grabbed it from the print bed I literally exploded like uncooked pasta in my hand. Super brittle and very weak. The print was an iteration of a model I printed last week so almost the same in size and thickness of walls etc and that old one is crazy strong. Then I tested all my old stuff and they are very strong. I printed one more time with the new colorfabb low warp and the same result, very brittle. More brittle than any plastic. Worse than PLA or whatever. As for the pro series Carbon fiber, It could be that it was unused for a long time. That I understand, but the same issue with new vacuum-sealed colorfabb. Is it just bad luck that 2 brands in a row are very brittle or is it something else? This is the first time I have had problems with PA-CF being brittle. Does anyone have experience with this with brand new filament? Why would brand new vacum sealed filament be brittle? Because it is 2 different brands but the same issue in a row, I am wondering if it isn't the filament but something with settings or printer? I am using recommended setting of the manufacturer of colorfabb low warp setings. For the matter hackers pro series carbon fiber filament I used Nylon X settings.

-

Hi SurfMagic,

Would it be possible to get a picture of your print? Strange that it is happening across different materials which makes me think that there is either something in your settings or hardware that is causing this. Does it happen along the layer lines or does the whole thing crack?

-

@fernando-silva said in Brittle PA-CF prints recently:

the layer lines or does the whole thing crack?

Layer line is very brittle

-

This is generally due to extruding below temperature and therefore the layers do not fuse properly. I recommend bumping up the temperature by 5 degrees and seeing if that resolves the problem.

-

@fernando-silva Thanks I tried 270c and the last print was definitely alot strong.then I started printing more stuff and now It extrudes l crumbs. So Iguess I got nozzle issues when printing lower temp previously. When you get one problem you run into more problems hehe...

-

I have solved it.

First it seems that I printed on the NylonX settings instead of the new settings I made for the Form Labs Low Warp. So I printed too low temp as pointed out. Second for some reason I changed then layer height to 0.1 instead of 0.2. That explains why the prints seem unusually smooth to me. This was a mistake. So first the prints where printed too cold,. Then the nozzle jammed as a result of too cold and too small layer heights. Got the nozzle cleaned and settings corrected. Prints good again.

-

@surfmagic Awesome hopefully it's smooth sailing from here on out!