Pulse XE Single Motor Gantry Lift

-

Pulse XE Single Motor Gantry Lift

https://www.thingiverse.com/thing:4884929The Problem:

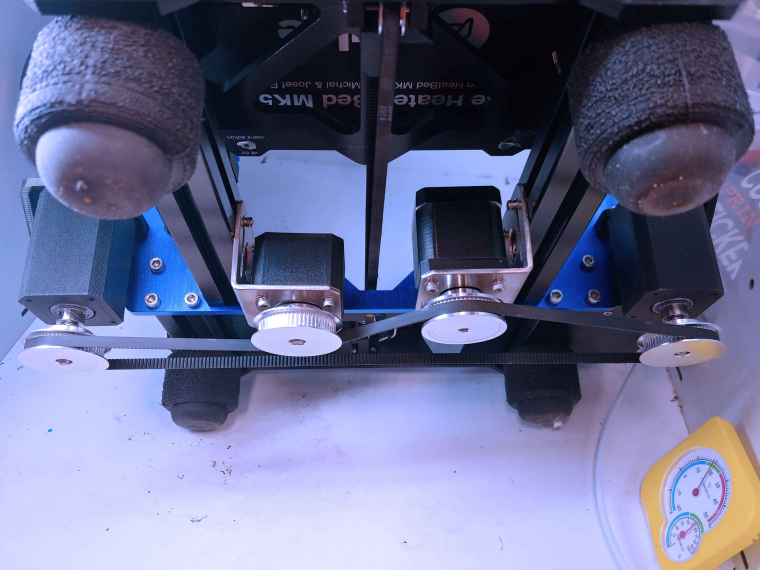

Z – axis lift gantry becomes out of sync during usage, nozzle to bed height becomes random either loosing bed adhesion or driving the nozzle into the print surface. Auto leveling between print layers/prints is just not realistic. Running both stepper motors from one driver will not keep gantry level.The Solution:

Single stepper motor dual Z-axis gantry lift system.Notes:

I have tested to over 5000 prints at the time of this writing without a single readjustment. I have dropped the driver current from 1.2A to 1.0A, preforms perfectly with less power. Z – axis pillow blocks are longer in order to keep the T8 shafts from bending. The two stepper pillow blocks mount in place of the z-axis motors, these are the longer 65mm blocks. The one short 30mm block is used a a belt tensioner next to the drive motor. You will need to cut a short piece of T8 lead screw for the 30mm belt tensioner block and add the two lock collars on either side of each of the bearings. It is suggested to repack your Abec 9 bearings with TinkSeal. This will give permanent lubrication as well as help seal out plastic abrasive dust. Use dental pick to carefully remove the rubber bearing seals. This will save you a headache down the road. Miscellaneous hardware will be needed depending on the size used. I suggest picking up a multi pack of bolt and T-nut hardware. I originally used M3, but this is too light for long term use.

2 - 65mm Stepper pillow blocks Long

1 – 30mm Stepper pillow block short

1 – Nema 17 48mm LDO/E3D stepper motor (same as x-axis motor)

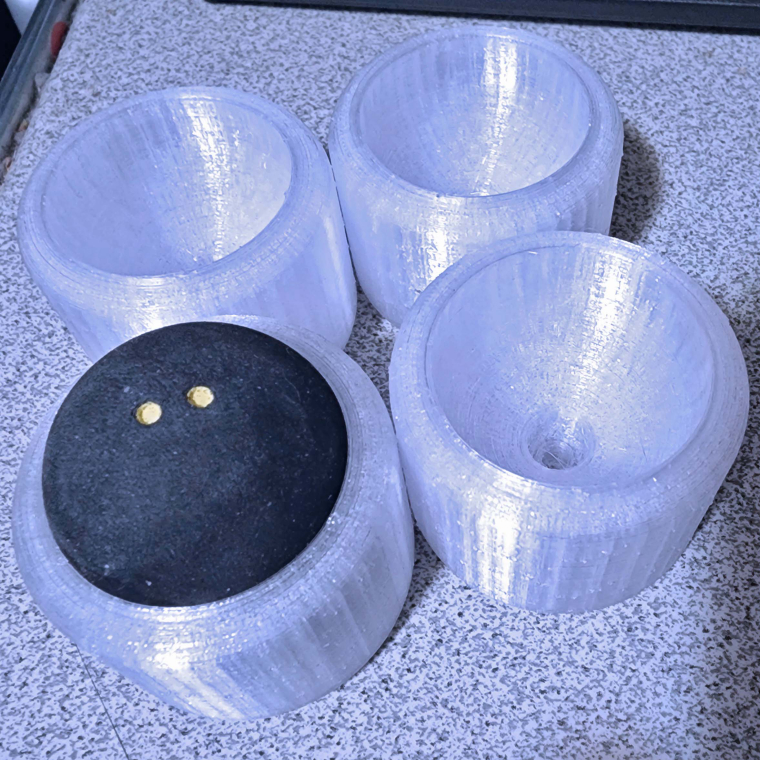

4 - Squash ball feet:

https://www.thingiverse.com/thing:46262073 - 60 Teeth 8mm Bore Aluminum Timing Pulleys

1 - 60 Teeth 5mm Bore Aluminum Timing Pulleys

2 - Nema 17 Stepper Motor Mounting Bracket, 304 Stainless Steel

1 - Timing Belt L=800mm W=6mm 400 Teeth in Closed Loop

4 - Lock Ring 8mm Shaft Lock Collar T8

6 - 608 RS Bearings ABEC 9 (RS = Rubber Seals)

1 - TinkSeal.com Bearing lubricant

1 - Dentist Pick

2- T8 600mm Lead Screw (cut to length)

Misc Bolt Hardware & Matching T-nuts

Print SettingsPrinter:

Pulse XE

Rafts:

Doesn't MatterSupports:

NoResolution:

0.25Infill:

35Filament brand:

MatterHackers

Filament color:

Black

Filament material:

CarbonFiber Nylon / PETG

Notes:

This is by far more reliable than the current MatterHackers setup. Cheaper to manufacture and does not limit your Z-axis height. With taller upper brackets and longer T8 screws, you could very possibly lift the hotend up to the bottom of the D frame. I am working on new brackets to gain 25-50mm higher Z.

-

Very cool mod. Nice work!

-

@larsbrubaker Thanks Lars! At the time of the mod, I was still running the Azteeg board and this solved many of the problems and headaches faced by both end users and MatterHacker staff. Even beginner/intermediate users can do this simple modification. I think I spent about $100.

I have since upgraded to the new Duet3 Mini 5+ board. I am working on the write up and will post it on your forums. I have all the Duet3 config files, printed hardware files and images already uploaded to my Github page. I understand that Duet isn't for everyone, but the Pulse XE now performs in the manner everyone wanted it to.

If MatterHackers produced a PulseDuet, I believe it would be very popular. And support for the printer would not be a burden to MatterHackers because users could go to the Duet3 forums. The support there is insane. They work with 3dprinters, laser, engraving, cnc and other projects. As long as you learn how to post in their forums, response time is usually in just minutes. They are very serious about selling Duet electronics and MatterHackers is already an official dealer.

-

@thwclw Yes, I am now over 10,000 prints into this project with no adjustment. This is the #1 mod needed for the Pulse.

-

What series is your PulseXE? I have the E series with the BigTreeTech SKR 1.4 turbo board upgrade they installed

-

@jennidianne I have E series also. I have Duet3D Mini 5+ now. No front display. This mod will work with electronics you use.

-

Printer x-axis is still perfectly level. I am in about 15,000 parts since the creation of the modification. I checked the clearances with my calipers and it is still right on. No longer worry about part separation or mid print failures from the gantry being out of sync. Before printing, I set Z=0, probe the bed in 106 spots, load height map and print.

-

Lifted feet for the lower pulleys. Also smooths out the harsh shaking while printing.