How to change filament on Pulse. It only backs up half way

-

Hello I am new to the Pulse XE. I have been printing with Nylon pro series with massive shrinkage so I wan tot change to the Nylon X and on the control panel I go to change filament and the nozzle heats and and the feeder backs up the filament a little bit then stops. Ok so no the filament is somewhere halfway between the 2 feeder motors. How do I now get i out. I cannot yank it past the first feeder motor. I would expect the first feeder motor to back up all the way out.

-

@surfmagic Ok solved it. By the way the nylon X was great. no warping, great adhesion and great shape.

-

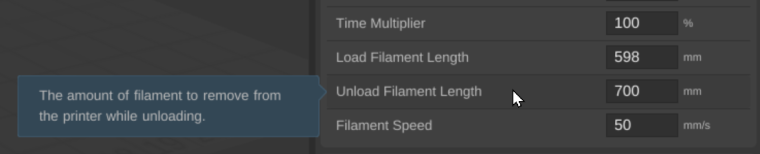

@surfmagic My pulse was spec'd to include a filament out sensor which it did not come with. However the sensor is set to on in printer settings and in mattercontrol. With those on my filament unload from mattercontrol always failed the 1st time, Doing it again always worked. Turn off the sensor in marlin and mattercontrol should solve that problem. you will need to do an m500 to save the setting in firmware. I have found that the load/unload lengths in mattercontrol do work. Load/unload on the lcd screen do not work because the matterhackers firmware has the limits set at 200. I can't currently compile it to change it though. (semi-opensource at best, with vague email responses from you know who)

-

@ibbro Matterhackers discontinued the use of the filament run out switch due to poor reliability. You can turn the feature on which activates the switch on the Azteeg board. I have the wiring diagram if needed. I printed the Matterhackers switch out. It is basically just a bearing that presses up against a microswitch. It looks cool, but it's janky. No wonder Matterhackers had a problem with it. You can buy decent filament switches for $5 on ebay and get it working.

-

@thwclw In general these settings are made for very advanced users, those building a custom machine (like you guys) or the original manufactures, that said, what would you like see improved in the documentation?

Setting this value will feed in or out the number of mm of filament specified. If it doesn't please let us know and we will get it fixed.

-

@thwclw I don't think that Lars works on the hardware side of these printers, just MatterControl, software, etc.

-

Here is the MatterHackers Github link(s)

https://github.com/MatterHackers

https://github.com/MatterHackers/PulseOpenSource

https://github.com/MatterHackers/Smoothieware

https://github.com/MatterHackers/MatterControl-Help

https://github.com/MatterHackers/PulseV1Firmware

https://github.com/MatterHackers/PulseV1Firmware/tree/EFrame/MarlinMatterHackers no longer uses Smoothieware, I suggest you upgrade to Marlin.

I have uploaded a copy of my firmware I last used on my Pulse XE 423s

Here is my repository:

https://github.com/vrysmlanml?tab=repositories

-

I struggled for months with my Azteeg board. It displayed defective behavior and I was sure that I had received a defective control board. After 80 or so emails back and forth with MattherHackers support, I gave up and added a Duet3D board, replacing the Azteeg board I had paid so much for. Turns out after talking to a friend who sells printers, it wasn't just my board, but all of them. This is not a problem that can be solved with firmware. Azteeg works for users who want a push button printer, but not so much for advanced users or production users like myself. The Duet3 board made the Pulse XE perform the way it should have from the beginning. But Duet is not for everyone, you really have to sit down and learn gcodes.

I don't know what advice to give you. This is what worked for me. I am sure the MatterHacker guys will throw tomatoes at me, but I speak the truth here. Duet3 control board with my single motor gantry lift made the Pulse XE a reliable, precision printer. The way it came from the factory just was more of a limited hobbyist printer.

-

@thwclw Some of my friends who build their own printers use auto gantry sync on their Marlin and Duet firmware and they say it works... But it only works between prints and I think it a band-aid fix. It is one more thing that can go wrong.

Single motor lift system cured 50% of the problems with the Pulse printer. The new firmware helped also. But in order to make the Pulse printer perform reliably (or at least as reliable as it can be), the duet board was a required upgrade.

Does your cnc machine run on Duet electronics?

-

@thwclw Try using my firmware on a new SDcard (keeping yours as is just in case). If the extruder runs backwards, I believe we can that without compiling Marlin.